Across industries, continents, and generations the discussion over AI and Generative AI is never-ending. And yes, it is making an impactful impression in the manufacturing arena too. According to Gartner, over 100 million people by 2026 are predicted to engage with robo-colleagues. That’s some interesting data. Isn’t it?

Industry 4.0, which is an era synonymous with smart manufacturing when blended with AI opens an avenue of opportunities. Defined by an assortment of powerful technologies such as Artificial Intelligence (AI), Machine Learning (ML), the Internet of Things (IoT), and Cloud, the primary objective of implementing these advanced digital technologies into manufacturing is to enhance efficiency, improve Return of Investment (ROI), and maintain competitiveness. Today, as more and more industries strive to improve revenue, and remain competitive the shift toward smart factories and intelligent manufacturing is no longer plan B.

Driven by hi-tech and advanced digital technologies, that enable manufacturers to increase efficiency, reduce costs, eliminate downtime, automate processes, and personalize products, not banking on this concept can expose businesses to a significant risk of falling behind in a highly competitive market, making the adoption of industry 4.0 and AI an absolute necessity.

Economists predict that the combined effect of AI with Industry 4.0 will significantly boost industrial profits, fueled by the rise of industrial automation and digital transformation. However, it won’t be wrong to conclude that the dawn of AI in Industry 4.0 fosters innovation including opportunities and challenges as manufacturers endeavor to redesign their business processes. Our blog is focused on understanding the fundamentals of AI in manufacturing and how AI is steering growth in this sector. We delve deep into its applications and shed light on key impact areas of this technology. Stay with us to learn all this and more.

AI has the potential to completely transform the manufacturing industry. Right from improving productivity, to reduction in expenses, AI makes an impactful impression. In real-world scenarios, bigger players in the industry are making the most of this technology while several smaller players need to realize the ease of getting their hands on AI solutions that can readily bring high value with lower costs.

With large volumes of data being generated on a daily basis by Industrial IoT (IIoT) and smart factories, AI-based solutions can be used in different ways to enhance the overall manufacturing landscape. Solutions like Machine learning and Deep Learning which are subsets of AI are widely used by manufacturing companies for better data analysis. Predictive maintenance often opts to be applied to production data to aid failure prediction and maintenance planning, resulting in reduced downtime and cost-effective maintenance for production lines. This is just the beginning. Many such applications of AI go together with Industry 4.0 and aid the manufacturing sector in a plethora of ways.

The AI in manufacturing market is experiencing remarkable growth as manufacturers have started to realize the immense value it can bring to business operations. AI in manufacturing is gaining traction on a large scale. Implementation of AI-driven solutions supported by machine learning, deep learning, predictive maintenance, and computer vision reflects a strategic move toward the modernization of manufacturing processes and staying ahead of the competition. Let’s find out what these key segments have in store.

Machine Learning:

Machine learning is one of the key drivers making an impact in the manufacturing space. Applied to large volumes of data related to production, products, and equipment, machine learning algorithms help deliver positive results on time-consuming aspects of the manufacturing process. Other ML-based technologies used in the manufacturing spectrum are predictive analysis, Intelligent process automation, computer vision, and neural networks.

Deep Learning:

Manufacturing companies are extensively using deep learning solutions to improve productivity, reduce production defects, increase capacity utilization, and lower maintenance costs. Despite generating vast amounts of data, most manufacturers haven’t effectively harnessed it. This is changing as deep learning becomes a strategic focus. According to McKinsey, deep learning models could potentially generate $1-2 trillion annually in supply chain management and manufacturing, underscoring its substantial value and transformative impact on the industry.

Ways in which AI is changing the Manufacturing Industry

Deploying AI in manufacturing can rapidly power efficiency and innovation. By making the overall manufacturing process more result-oriented, error-free, and foolproof, manufacturers are making the most of AI to optimize productivity and streamline operations, while reducing costs. As AI can be deployed to capitalize on digital technology and enhance core manufacturing operations, it can simultaneously improve human abilities by bringing out the best from the combination of humans and machines.

Let’s find out the three ways in which AI is changing the face of manufacturing.

1. Operational Efficiency

AI significantly boosts operational efficiency in manufacturing by eliminating or automating repetitive tasks. This allows employees to concentrate on high-value activities that demand more resources, thus accelerating production and increasing business output. By implementing streamlined processes tailored to each manufacturer’s unique system, AI minimizes downtime and ensures optimal resource allocation, leading to substantial efficiency gains.

Furthermore, AI optimizes energy consumption through the efficient scheduling of processes during high-resource periods, reducing delays and long response times. Predictive maintenance on the other hand also contributes to planning repairs during inactive hours, leading to a decrease in operational costs associated with unplanned downtimes. Additionally, by embracing AI, manufacturers can be rest assured to gain valuable business insights from existing data to be able to operate more efficiently.

2. Improved Agility and Quality

By embracing the goodness of agile manufacturing, businesses are in the position to easily withstand changes and fluctuations in the market, handle unforeseen circumstances in a more prepared manner and stay flexible. AI plays an important role in enhancing this agility by processing and interpreting information that might escape human notice, facilitating smoother collaboration between teams and departments. This leads to the automation of complex production tasks and improvements in quality control.

With predictive quality control, AI minimizes defects, ensuring consistent product quality and providing real-time, precise business outcomes. AI equips manufacturers with the flexibility and quality improvements essential for progressing, meeting customer expectations, and maintaining a competitive edge in the market.

3. Improved Decision Making

AI-generated insights empower manufacturing leaders to make informed, data-driven decisions by providing essential connectivity, tools, and automation to achieve unparalleled precision and quality for customers.

By leveraging machine learning algorithms, AI systems can analyze customer buying patterns and deliver actionable insights to business leaders. This information allows manufacturers to adapt processes to better meet customer needs and requirements. AI-powered inspection tools can identify defects on production lines and detect faults immediately, alerting human workers to issues before they escalate. This proactive approach enables manufacturers to quickly decide on the necessary steps to fix errors, preventing further disruptions.

Additionally, AI’s ability to track supplies and prevent bottlenecks in real-time provides manufacturers with the critical data needed to make forward-thinking decisions that minimize impact on production. By analyzing vast amounts of data and recommending optimal production solutions, AI significantly influences how manufacturing leaders operate, enhancing decision-making with crucial business insights and driving continuous improvement.

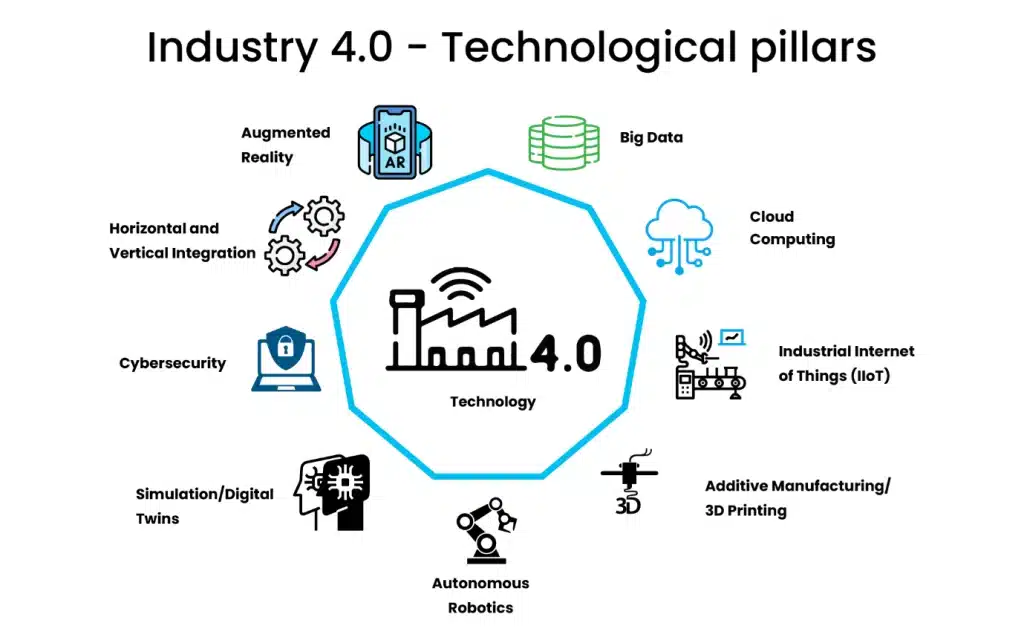

Let’s now explore the key technological pillars of Industry 4.0.

9 Key Technology Pillars of Industry 4.0

Big Data in Industry 4.0 comes from assets, equipment, and IoT devices, along with external sources like customer reviews and market trends. AI and machine learning do thorough analysis of this data in real-time, boosting decision-making and automation to enhance efficiency and productivity.

Supporting AI, machine learning, and IoT integration, cloud computing plays a fundamental role in Industry 4.0. It provides a scalable platform to store data and enables real-time communication, enhancing efficiency and productivity across cyber-physical systems.

The smart industry is largely dependent on horizontal integration for smooth coordination across production and supply chains, and vertical integration is responsible for streamlined data flow via organizational layers. This integration connects production with other critical business processes such as research and development, and sales, by eliminating data silos and streamlining operations.

AR or Augmented Reality is the technology that gives the manufacturing world an extra dimension by connecting digital content to real-world views making them available to the naked eye. This technology enables employees to seeIoT data and instructions through smart glasses or mobile devices. It enhances maintenance, service, quality assurance, and training.

Critical to Industry 4.0, IIoT, makes use of sensors and RFID (Radio Frequency Identification) tags to deliver real-time data on machinery and products, improving supply chains, product design, and inventory management.

Originally used for rapid prototyping, 3D printing now supports mass customization and on-demand production. It allows design files to be stored virtually and printed as needed, cutting costs and minimizing reliance on off-site manufacturing.

In Industry 4.0, autonomous robots use AI, sensors, and machine vision to perform tasks with minimal human input, from inventory scanning to pick-and-place operations.

A digital twin is a virtual model of a real-world machine or system, created using IoT sensor data. It helps businesses analyze and enhance performance and maintenance, enabling operators to pinpoint issues, predict problems, and boost uptime.

In Industry 4.0, robust cybersecurity is crucial due to increased connectivity and Big Data use. Employing Zero Trust architecture along with machine learning and blockchain helps automate threat detection and response, reducing the risk of data breaches and production interruptions.

Mitigating Future Issues

Applying AI-driven solutions can assist manufacturers predict when or if questions are related to the functioning or breakdown of an equipment, giving them more room to plan maintenance and repair activities before the actual breakdown takes place.

Quality Control and Defect Detection

AI-powered video analytics using computer vision can inspect products with exceptional accuracy. These systems use multiple cameras and sensors to capture and analyze product images in real-time, quickly spotting defects or anomalies. This cutting-edge technology is crucial for ensuring that only top-quality products reach the market, which helps minimize waste and boost customer satisfaction.

Design Alternatives

By using machine learning in generative design, manufacturers can simulate the design developed by engineers, enabling them to rapidly produce hundreds of design options for the same product.

Efficient inventory management is the lifeline of any production unit. Deploying AI in manufacturing can be extremely beneficial in optimizing inventory management by strategically predicting demand, observing usage patterns, and automatically restocking the inventory when the order line reaches red. This not only promotes lean inventory management but ensures the production line never runs out of overflows with stock.

Safety is central to any manufacturing business. And AI plays an essential role in strengthening safety protocols. Deploying AI solutions in manufacturing safety systems can aid continuous monitoring of industrial environments and give prompt insights on the detection of any potential hazard or deviation from standard safety procedures. Furthermore, these systems can issue immediate alerts, effectively averting accidents and safeguarding the well-being of employees, as well as upholding the integrity of the manufacturing workflow.

Generative AI revolutionizes manufacturing by creating innovative design solutions and optimizing production processes. It leverages algorithms to generate multiple design alternatives, simulate performance, and enhance efficiency. This technology makes way for rapid prototyping and customization, allowing manufacturers to explore various design options and refine products based on performance data. Generative AI helps accelerate product development, reduce costs, and improve overall manufacturing flexibility and quality.

Calsoft being one of the early adopters of Gen AI helps businesses explore the power of Large Language Models and realize the benefits of this promising technology.

Rather than a mere conclusion, this section highlights the ongoing potential of AI across industries. The integration of sensors, robotics, and advanced software is empowering smart industries to leverage data for superior decision-making. As AI continues to evolve, its ability to analyze and interpret vast amounts of information will drive further innovation and efficiency. The future promises even greater advancements, ensuring AI remains a crucial tool for progress and transformation in manufacturing and beyond.

Calsoft being a technology-first company, has translated successful digital transformations across industries. Our expertise in Gen AI, analytics & ML can be deployed to gain operational efficiency.